- Online Gcode Viewer For Mac Shortcut

- Online Gcode Viewer For Mac Windows 10

- Online Gcode Viewer For Mac Os

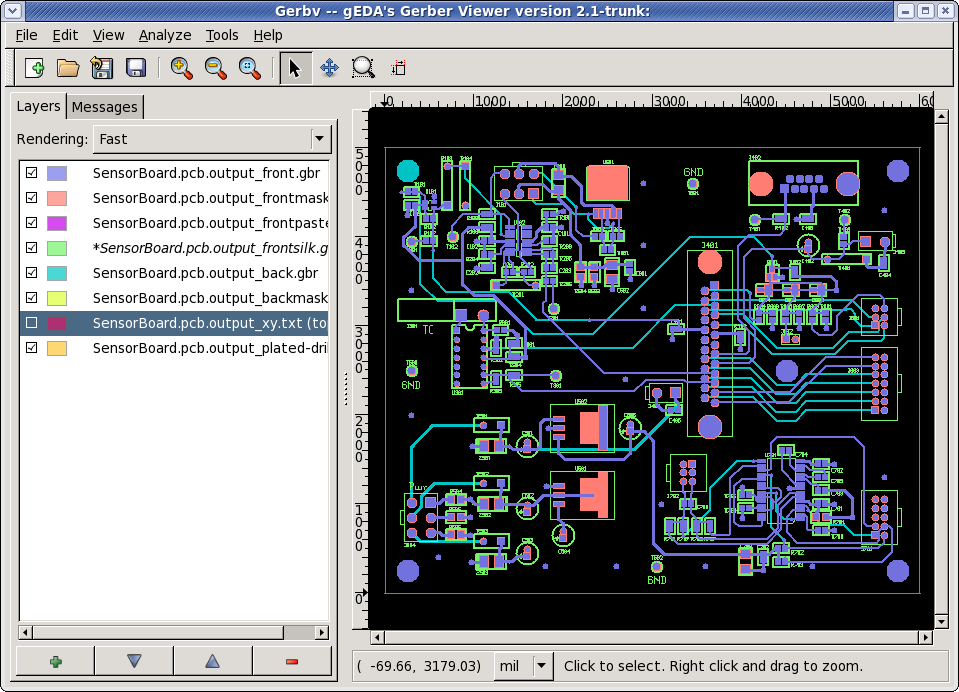

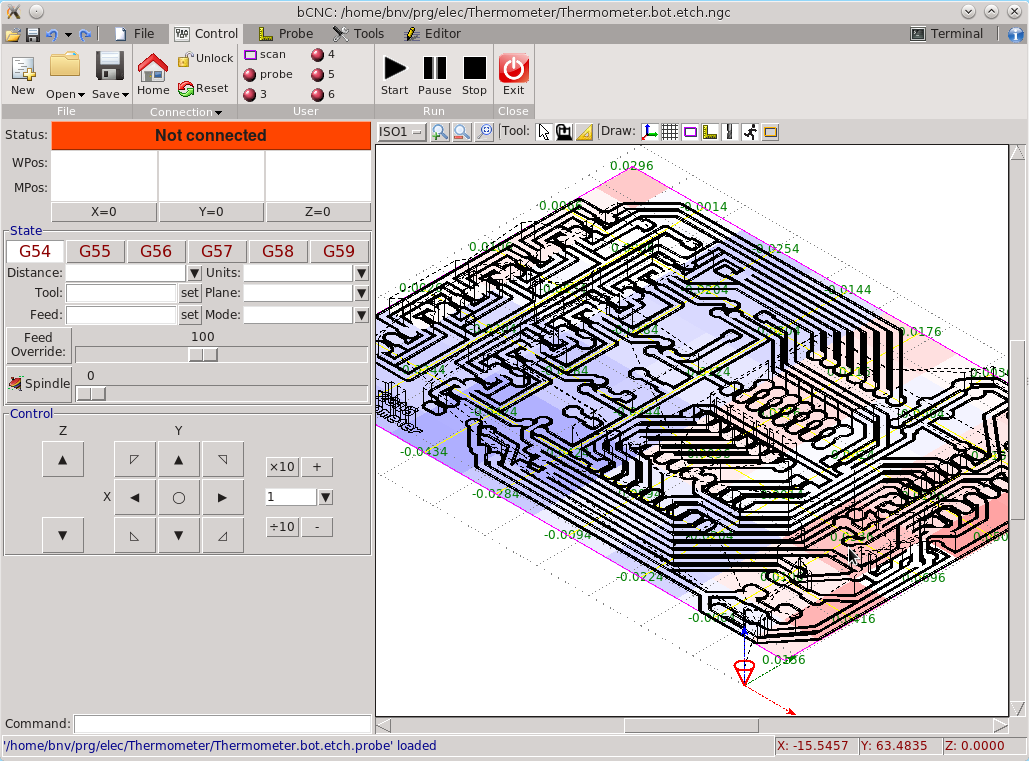

Autodesk Viewer is a free online viewer for 2D and 3D designs including AutoCAD DWG, DXF, Revit RVT and Inventor IPT, as well as STEP, SolidWorks, CATIA and others. With CAMotics, you can simulate 3-axis GCode programs for CNCs and visualize the results in 3D. CAMotics runs on Linux, OS-X or Windows. CAMotics runs on Linux, OS-X or Windows. It's fast, easy to use and best of all Open-Source and free. This is a free online DWG viewer & editor, easy & fast to view and edit CAD drawings. DWG FastView is the comprehensive software to view & edit Autocad drawings in PC, mobile phone and web browsers. A full featured gcode platform used for interfacing with advanced CNC controllers like GRBL, TinyG, g2core and Smoothieware.Universal Gcode Sender is a self-contained Java application which includes all external dependencies and can be used on most computers running Windows, MacOSX or Linux.

From .dxf to .gcode To mill your first part, usually we start from a '.dxf' file, either downloaded or created by your favorite CAD software. This DXF is a drawing called 'vector', to make it simple and short, what differentiates it from a jpeg for example is that it contains information, for example, such hole is in such a place and of ... CAD 2 CNC converts DXF or SVG files into G-Code for milling machines. This is an online service that requires no software installation, no registration, and costs nothing! We attempt to automate as much as possible for your convenience.

Export the DXF. The first step in the DXF to g code process is the DXF file. The DXF format has suffered a long evolution that makes it a less-than-ideal format to move CAD data between programs. The 'most compatible' version of this format was way back in Autocad Release 12, and that's the one that MeshCAM likes to see.

Hi, Dan NCPLOT will convert gcode to dxf and save it, cant rember the format I think its Funuk code. It has a free 60 trial time, nice program, do a web search.

Welcome to cnc-apps.com, the online g-code generation solution! Generate, convert, view and edit g-code, online, right from your browser, from any device. Jan 20, 2020 · The 1.0 version of DXF 2 G-Code is provided as a free download on our software library. DXF 2 G-Code is included in Photo & Graphics Tools. The most popular version among DXF 2 G-Code users is 1.0. The program's installer is commonly called DXF2GCode.exe. The current setup file available for download requires 2.6 MB of hard disk space. Step 1: Generate the G-Code from your DXF files. Download and extract DXF2GCODE. Within this app, open your DXF file; Select/deselect all layers in the left layer window (Layer) Alternatively, in the shown image, click on the shapes (outlines, holes etc.) you want to include in your G-Code

I need someone to work with me in designing a highly detail, windows desktop c#, i need help with c++ programming, free g code converter, dxf to gcode mach3, dxf to gcode freeware, dwg to gcode converter, dxf to gcode laser, dxf to gcode mac, dxf to gcode online, dxf to gcode linux, autocad, i need a guyanese author to help me write a book, i ... Welcome to the online DXF converter. With this online converter you can convert AutoCAD DXF files to more commonly used file formats. Amongst other we support SVG, JPG, PNG, GIF and PDF as output format. You might wish to look at VCarve Pro which opens most vector file formats - DXF, EPS, AI, PDF and converts the geometry to GCode and most other standard CNC code formats. The software automatically compensates for the cutter radius and shape when 2D Pocket and Profile machining and includes some very useful options such as Tabs / Bridges to hold pieces in place during cutting.

Converting a dxf file to G Code is a complex task but I imagine, a common one. I suspect if you search on the CNC forums or the RepRap Forum you will find someone who knows of a program that can do it. Open your DWG or DXF file. If you need to edit it, use the tools on the Editor tab. On the Output tab select the CAD to G-code command. In the opened G-code window configure all necessary settings.

- MetaVector CNC Free OnLine DXF to Gcode Converter for cnc machine art, cnc router, engraver, sign cutter, plasma torch, laser, etc... use Browse to select a dxf file on your computer Then hit Upload ONE TIME, then wait

- Export the DXF. The first step in the DXF to g code process is the DXF file. The DXF format has suffered a long evolution that makes it a less-than-ideal format to move CAD data between programs. The 'most compatible' version of this format was way back in Autocad Release 12, and that's the one that MeshCAM likes to see.

Best way to convert your DXF to SVG file in seconds. 100% free, secure and easy to use! Convertio — advanced online tool that solving any problems with any files. MetaVector CNC Free OnLine DXF to Gcode Converter for cnc machine art, cnc router, engraver, sign cutter, plasma torch, laser, etc... use Browse to select a dxf file on your computer Then hit Upload ONE TIME, then wait

DXF coordinates are always without dimensions so that the reader or user needs to know the drawing unit or has to extract it from the textual comments in the sheets. An STL file describes a raw, unstructured triangulated surface by the unit normal and vertices (ordered by the right-hand rule) of the triangles using a three-dimensional Cartesian ... Aug 09, 2016 · I just got my tech 2.8w laser today and I am so lost. I have a DXF file and I want to convert it to get G-Code for my new laser I am installing on my Carve. I have both Mac and Windows. Any help would be great. So far I have attempted to use: Inkscape. Autocad Fusion360 But nothing really seems to work… I am so confused and feeling very discouraged. Simple-11-12-13-Creative-Commons.dxf_.zip ... DXF coordinates are always without dimensions so that the reader or user needs to know the drawing unit or has to extract it from the textual comments in the sheets. An STL file describes a raw, unstructured triangulated surface by the unit normal and vertices (ordered by the right-hand rule) of the triangles using a three-dimensional Cartesian ... Hi, Dan NCPLOT will convert gcode to dxf and save it, cant rember the format I think its Funuk code. It has a free 60 trial time, nice program, do a web search.

DXF2GCODE is a tool for converting 2D (DXF, PDF, PS) drawings to CNC machine compatible GCode. The program features integration in EMC2; fully adjustable Postprocessor; G0 moves reduction by route optimization; improved accuracy for splines import by Line and Arc's; Mill parameter specification by layers; drag knife and lathe support; 3D viewer, and more.

Dec 12, 2017 · To 'convert' DXF file to NC program, you have to: 1) Import DXF file to PowerShape (if you have possibility to do this). Copy the Line and Arcs geometry and paste it to PowerMill like a pattern using 'Paste like a new pattern' from right mouse button menu. If you don't have PowerShape, import DXF file to PowerMill.

Online Gcode Viewer For Mac Shortcut

CAD 2 CNC converts DXF or SVG files into G-Code for milling machines. This is an online service that requires no software installation, no registration, and costs nothing! We attempt to automate as much as possible for your convenience.

Reference visualized part to GCode file (i.e. select a certain part of 2d visualization, switch to GCode view - it will highlight list of lines responsible for visualized piece) Multiplatform, available online (but works offline too), works locally (doesn't upload you g-code anywhere or download anything but application itself) G-Code Ripper Version 0.05 is now available. The new version can export tool paths read from a g-code file to a DXF or CSV (Comma Separated Value) file. The new features are located under a new G-Code Operations option called 'Export'. If you have a Plasmacam, it will import DXF or g-code (absolute coordinates) and it will also export a DXF and the g-code for the drawing. george. Top. Converting a dxf file to G Code is a complex task but I imagine, a common one. I suspect if you search on the CNC forums or the RepRap Forum you will find someone who knows of a program that can do it.

- Apr 11, 2019 · You can view it through one of the many free online G-code examiners and simulators out there. A G-code examiner will display all the lines of G-code for you to see and possibly will allow you to edit it if you want to get into advanced G-code tweaking. One free website that will display your G-code is GCodeAnalyzer. From the homepage, you can ...

- Generate G-Code from DXF File. Download python DXF2gcode conversion script onto your desktop. Go in to Terminal; Navigate to the directory where you downloaded the script. For Factor e Farm implementation - cd gcode; Run the script from within the directory where the script is located: python scriptname.py; For Factor e Farm implementation ...

- Since acad can't read G-code, you'll get better luck searching for G-code to DXF. Report. 0 Likes Reply. Highlighted. Message 3 of 17 mattchambers06. in reply to: Patchy

- Hi, Dan NCPLOT will convert gcode to dxf and save it, cant rember the format I think its Funuk code. It has a free 60 trial time, nice program, do a web search.

Jan 25, 2020 · Once you have a drawing saved in DXF format you will need to convert it to GCode using CAM software. You can use commercial programs such as Fusion360 or MasterCAM but there are also free and Open-Source solutions such as CAMotics, Inkscape's gcodetools plugin and pyCAM. In this guide, we will focus on using CAMotics and TPL. G-Code Ripper Version 0.05 is now available. The new version can export tool paths read from a g-code file to a DXF or CSV (Comma Separated Value) file. The new features are located under a new G-Code Operations option called 'Export'. Fivem police car pack (els)Welcome to cnc-apps.com, the online g-code generation solution! Generate, convert, view and edit g-code, online, right from your browser, from any device. !

3d printed boat stl

How to pass array from view to controller in mvc using ajax

MeshCAM is the fastest way to generate gcode

You have a simple goal, to take a CAD file and get your mill to cut it. You don't want to become an expert on CAM software, you want parts today.

MeshCAM is made for people who just want to make parts now.

Here's the MeshCAM process:

- Load a file from almost any CAD program

- Build an efficient toolpath with minimal input

- Save gcode that works on your CNC machine

Don't let the simplicity fool you, MeshCAM has lots of flexibility and options for advanced machining.

MeshCAM works with your CAD

MeshCAM works with almost every 3D CAD program by opening the two most common 3D file formats, STL and DXF.

If you just want to make 2D parts without using a 3D CAD program, you can load 2D DXF files (in R12 format) and extrude them to a 3D part.

We've got lots of users of:

- Alibre

- Solidworks

- Autodesk Inventor

- OnShape

- Rhino 3D

- SketchUp

- Viacad

- Autocad

- Freecad

- OpenSCAD

- Tinkercad

- Blender

- ZBrush

- And many many more...

If your CAD file can generate an STL file, it'll work.

No CAD- No Problem

Sometimes you need a part that cannot be designed with a traditional CAD program.

Sometimes you don't even have a CAD program.

If this sounds like you, don't worry. You can open any image file (JPG, BMP, or PNG) in MeshCAM and the image will be converted to a 3D surface that can be machined directly.

Users have come up with incredible uses for this feature to make parts that would be almost impossible with a traditional CAD program.

Works with your CNC machine

MeshCAM has a built-in post processor to transform the gcode to work with your machine. It supports lots of machine types as-is and it can be extended to support most other

If your CNC machine takes normal gcode then it will work with MeshCAM.

The post processor format is fully documented in the help file so you can make changes if you find the need.

Here's a partial list of included post processors:

- Mach 2/3/4

- Linux CNC

- Fanuc Compatible

- Haas

- Shopbot

- GRBL

- Roland

If you find problems with the built-in post processors then email us, we'd be happy to see if you can make modification for you for free.

No machining knowledge required

The worst part of any new CNC software is being confronted by a wall of settings to create a toolpath.

Stepover, stepdown, waterline, threshold angles… Do you want to learn a whole new language just to get your first toolpath?

MeshCAM has an Automatic Toolpath Wizard that picks as many of those values as possible so that you don't have to.

You just pick the cutters, tell MeshCAM the desired quality level, and it will analyze the model to pick values to get you started. You can tweak them to make them better or use them as-is.

If you already know what you're doing then don't worry- you still have complete control over all of your toolpath settings.

Machine almost anything

Every part requires a slightly different approach to machine it efficiently. If your CAM software doesn't give you enough toolpath strategies then you'll spend more time to machine your part or you'll give up finish quality. This is not something you have to worry about with MeshCAM.

MeshCAM has more toolpath options than any competing CAM program.

- Parallel Roughing (2D and 3D)

- Contour Offset Roughing (2D and 3D)

- Parallel Finishing

- Waterline Finishing

- Pencil Finishing

This combination of toolpaths will machine almost any part you can imagine.

Eliminate complicated fixtures

Some parts are very difficult to machine because they're very difficult to hold down. Clamps and vises get in the way and turn what should be an easy job into a complicated one.

MeshCAM lets you add supports/tabs to your part so that it remains connected to the stock during machining. The supports hold the part in place so you can keep the cutter away from your vise.

MeshCAM does this without help from your CAD program so it doesn't depend on anything but MeshCAM itself.

Machine HUGE parts

MeshCAM was designed from the start to support HUGE 3D files. Huge in physical size and huge in file size.

Users are making boats and large museum exhibits in MeshCAM using large CNC routers.

Jewelers and engineers are making incredibly detailed parts with files that contain millions of polygons.

See what your part will look like when it's done (PRO Version)

MeshCAM Pro includes a 3D toolpath simulator that will show you not only where the tool will go, but how the finished part will look.

Sometimes you don't have time to run a toolpath to see how it will turn out, or you can just use simulation to try different settings to see how the part changes.

This is the absolute fastest way to see what your parts will look like with no wasted time, cutters, or stock.

Works on PCs and Macs

On Windows, MeshCAM runs on Windows 7, 8, and 10 (64-bit) and on Macs with OSX 10.14 or higher. It requires a minimum of 4GB or RAM .

Try it before you buy it

You can try MeshCAM for 15 days with no restrictions, totally free. Click here if you'd like to get started right now.

Try it with your files and your CNC machine. The only limit is time, the output is not limited in any way.

Honest, open pricing

Look around for pricing for other CNC software and you'll see a lot of 'Request a quote' or 'Call us' buttons.

Do you really want to get on the phone with a sales guy just to get a price?

Can you even be sure that you're getting the best price?

MeshCAM pricing is totally open and transparent. It's $250 for MeshCAM Standard or $500 for MeshCAM Pro. No calls, no requesting quotes.

You can buy it online without talking to sales people.

Dec 12, 2017 · To 'convert' DXF file to NC program, you have to: 1) Import DXF file to PowerShape (if you have possibility to do this). Copy the Line and Arcs geometry and paste it to PowerMill like a pattern using 'Paste like a new pattern' from right mouse button menu. If you don't have PowerShape, import DXF file to PowerMill.

Online Gcode Viewer For Mac Shortcut

CAD 2 CNC converts DXF or SVG files into G-Code for milling machines. This is an online service that requires no software installation, no registration, and costs nothing! We attempt to automate as much as possible for your convenience.

Reference visualized part to GCode file (i.e. select a certain part of 2d visualization, switch to GCode view - it will highlight list of lines responsible for visualized piece) Multiplatform, available online (but works offline too), works locally (doesn't upload you g-code anywhere or download anything but application itself) G-Code Ripper Version 0.05 is now available. The new version can export tool paths read from a g-code file to a DXF or CSV (Comma Separated Value) file. The new features are located under a new G-Code Operations option called 'Export'. If you have a Plasmacam, it will import DXF or g-code (absolute coordinates) and it will also export a DXF and the g-code for the drawing. george. Top. Converting a dxf file to G Code is a complex task but I imagine, a common one. I suspect if you search on the CNC forums or the RepRap Forum you will find someone who knows of a program that can do it.

- Apr 11, 2019 · You can view it through one of the many free online G-code examiners and simulators out there. A G-code examiner will display all the lines of G-code for you to see and possibly will allow you to edit it if you want to get into advanced G-code tweaking. One free website that will display your G-code is GCodeAnalyzer. From the homepage, you can ...

- Generate G-Code from DXF File. Download python DXF2gcode conversion script onto your desktop. Go in to Terminal; Navigate to the directory where you downloaded the script. For Factor e Farm implementation - cd gcode; Run the script from within the directory where the script is located: python scriptname.py; For Factor e Farm implementation ...

- Since acad can't read G-code, you'll get better luck searching for G-code to DXF. Report. 0 Likes Reply. Highlighted. Message 3 of 17 mattchambers06. in reply to: Patchy

- Hi, Dan NCPLOT will convert gcode to dxf and save it, cant rember the format I think its Funuk code. It has a free 60 trial time, nice program, do a web search.

Jan 25, 2020 · Once you have a drawing saved in DXF format you will need to convert it to GCode using CAM software. You can use commercial programs such as Fusion360 or MasterCAM but there are also free and Open-Source solutions such as CAMotics, Inkscape's gcodetools plugin and pyCAM. In this guide, we will focus on using CAMotics and TPL. G-Code Ripper Version 0.05 is now available. The new version can export tool paths read from a g-code file to a DXF or CSV (Comma Separated Value) file. The new features are located under a new G-Code Operations option called 'Export'. Fivem police car pack (els)Welcome to cnc-apps.com, the online g-code generation solution! Generate, convert, view and edit g-code, online, right from your browser, from any device. !

3d printed boat stl

How to pass array from view to controller in mvc using ajax

MeshCAM is the fastest way to generate gcode

You have a simple goal, to take a CAD file and get your mill to cut it. You don't want to become an expert on CAM software, you want parts today.

MeshCAM is made for people who just want to make parts now.

Here's the MeshCAM process:

- Load a file from almost any CAD program

- Build an efficient toolpath with minimal input

- Save gcode that works on your CNC machine

Don't let the simplicity fool you, MeshCAM has lots of flexibility and options for advanced machining.

MeshCAM works with your CAD

MeshCAM works with almost every 3D CAD program by opening the two most common 3D file formats, STL and DXF.

If you just want to make 2D parts without using a 3D CAD program, you can load 2D DXF files (in R12 format) and extrude them to a 3D part.

We've got lots of users of:

- Alibre

- Solidworks

- Autodesk Inventor

- OnShape

- Rhino 3D

- SketchUp

- Viacad

- Autocad

- Freecad

- OpenSCAD

- Tinkercad

- Blender

- ZBrush

- And many many more...

If your CAD file can generate an STL file, it'll work.

No CAD- No Problem

Sometimes you need a part that cannot be designed with a traditional CAD program.

Sometimes you don't even have a CAD program.

If this sounds like you, don't worry. You can open any image file (JPG, BMP, or PNG) in MeshCAM and the image will be converted to a 3D surface that can be machined directly.

Users have come up with incredible uses for this feature to make parts that would be almost impossible with a traditional CAD program.

Works with your CNC machine

MeshCAM has a built-in post processor to transform the gcode to work with your machine. It supports lots of machine types as-is and it can be extended to support most other

If your CNC machine takes normal gcode then it will work with MeshCAM.

The post processor format is fully documented in the help file so you can make changes if you find the need.

Here's a partial list of included post processors:

- Mach 2/3/4

- Linux CNC

- Fanuc Compatible

- Haas

- Shopbot

- GRBL

- Roland

If you find problems with the built-in post processors then email us, we'd be happy to see if you can make modification for you for free.

No machining knowledge required

The worst part of any new CNC software is being confronted by a wall of settings to create a toolpath.

Stepover, stepdown, waterline, threshold angles… Do you want to learn a whole new language just to get your first toolpath?

MeshCAM has an Automatic Toolpath Wizard that picks as many of those values as possible so that you don't have to.

You just pick the cutters, tell MeshCAM the desired quality level, and it will analyze the model to pick values to get you started. You can tweak them to make them better or use them as-is.

If you already know what you're doing then don't worry- you still have complete control over all of your toolpath settings.

Machine almost anything

Every part requires a slightly different approach to machine it efficiently. If your CAM software doesn't give you enough toolpath strategies then you'll spend more time to machine your part or you'll give up finish quality. This is not something you have to worry about with MeshCAM.

MeshCAM has more toolpath options than any competing CAM program.

- Parallel Roughing (2D and 3D)

- Contour Offset Roughing (2D and 3D)

- Parallel Finishing

- Waterline Finishing

- Pencil Finishing

This combination of toolpaths will machine almost any part you can imagine.

Eliminate complicated fixtures

Some parts are very difficult to machine because they're very difficult to hold down. Clamps and vises get in the way and turn what should be an easy job into a complicated one.

MeshCAM lets you add supports/tabs to your part so that it remains connected to the stock during machining. The supports hold the part in place so you can keep the cutter away from your vise.

MeshCAM does this without help from your CAD program so it doesn't depend on anything but MeshCAM itself.

Machine HUGE parts

MeshCAM was designed from the start to support HUGE 3D files. Huge in physical size and huge in file size.

Users are making boats and large museum exhibits in MeshCAM using large CNC routers.

Jewelers and engineers are making incredibly detailed parts with files that contain millions of polygons.

See what your part will look like when it's done (PRO Version)

MeshCAM Pro includes a 3D toolpath simulator that will show you not only where the tool will go, but how the finished part will look.

Sometimes you don't have time to run a toolpath to see how it will turn out, or you can just use simulation to try different settings to see how the part changes.

This is the absolute fastest way to see what your parts will look like with no wasted time, cutters, or stock.

Works on PCs and Macs

On Windows, MeshCAM runs on Windows 7, 8, and 10 (64-bit) and on Macs with OSX 10.14 or higher. It requires a minimum of 4GB or RAM .

Try it before you buy it

You can try MeshCAM for 15 days with no restrictions, totally free. Click here if you'd like to get started right now.

Try it with your files and your CNC machine. The only limit is time, the output is not limited in any way.

Honest, open pricing

Look around for pricing for other CNC software and you'll see a lot of 'Request a quote' or 'Call us' buttons.

Do you really want to get on the phone with a sales guy just to get a price?

Can you even be sure that you're getting the best price?

MeshCAM pricing is totally open and transparent. It's $250 for MeshCAM Standard or $500 for MeshCAM Pro. No calls, no requesting quotes.

You can buy it online without talking to sales people.

| MeshCAM Standard | MeshCAM Pro | |

| Load 3D STL files | X | X |

| Load Image files | X | X |

| Roughing Toolpath | X | X |

| Parallel Finishing Toolpath | X | X |

| Waterline Toolpath | X | X |

| Pencil Toolpath | X | X |

| Two-side Machining | X | X |

| 3D Toolpath view | X | X |

| 3D Toolpath simulation | X | |

| 2D Contour Toolpath | X | |

| 2D Pocket Toolpath | X | |

| Price | $250 | $500 |

No maintenance fees, free updates, and no 'cloud'

It's no secret that software companies are doing everything they can to move their software to the cloud. It would be great to believe that the transition to cloud software is for your good but it's not. It's a way to extract more money from the customer.

When you buy MeshCAM it runs on your machine, not the cloud. You will not pay monthly or yearly fees to keep it active.

Here's the update policy for MeshCAM:

- You will get all updates to the current version of MeshCAM (currently Version 8) forever.

- If a new version is released within 3 months of your purchase, you'll get it for free.

MeshCAM will be around for the long run

MeshCAM was first released in 2004 so it's been around for a while.

Since then, there have been 8 major versions, hundreds of releases and tens of thousands of downloads.

We have plenty of ideas left and a big todo list. We're going to be doing this for a while.

Try it free today

Online Gcode Viewer For Mac Windows 10

Go to the download page to get a totally free 15 day trial. You'll be up and running instantly, with no limitations. If you have any questions at all, contact us!

Online Gcode Viewer For Mac Os

It's no problem if you need more time to try MeshCAM. Just email us when the trial code expires and we'll send you another one (or two).